SamEnSo – Precision Automation & Surface Solutions

🔍 Precision Quality Management

- AI-based visual inspection

- Submicron laser sensors

- Touch probes for dimensional checks

- MES/ERP traceability logging

- Tier-1 quality compliance

🏭 Factory Automation

- Servo + pneumatic hybrid SPMs

- RFID + AGV integration

- IoT-based warehouse automation

- Dual-language PLC & HMI

- Old equipment retrofitting

🤖 Robot Integration

- Pick & place with sensors

- Collaborative safe robots

- Vision inspection robot cells

- FANUC, Omron, Yaskawa supported

- Remote HMI + digital twin

💧 Wet Blasting Systems

- Portable, medium & trolley types

- Closed-loop slurry reuse

- Custom nozzles & pressures

- Japanese HMI + recipe saving

- Auto, Medical, Aerospace-ready

⚙️ Engineering & Programming

- 2D to 3D CAD conversion

- JIS-compliant drawings & GD&T

- PLC, HMI, SCADA development

- Robot + embedded programming

- Full CAD → Robot → PLC support

🧠 Why SamEnSo?

- Japan + India field support

- Bilingual documentation (JP/EN)

- 10+ years of reliable system design

- Proven in Tier-1 factories

- Training, manuals, and simulation

Industries We Serve

Precision automation & surface solutions for Japan’s leading sectors

🚗 Automotive & EV Industry

- Wet blasting for gearboxes, casings, housings

- Robotic assembly for ECU, connectors

- AI vision systems for defect detection

- AGV logistics & PLC-integrated traceability

❄️ HVAC & Refrigeration Equipment

- Surface finishing for coils, fins, casings

- Pipe automation for bending, brazing

- Vision systems for cover alignment & defects

- Barcode + MES-integrated workflows

🏭 Industrial Machinery & Tooling

- Heavy part finishing & robot handling

- Custom automation with CAD to PLC

- Retrofitting for logic & voltage localization

- Smart diagnostics with HMI + SCADA

🧪 Medical, Electronics & Precision

- Cleanroom automation for micro components

- Wet blasting for surgical tools, implants

- Micro-defect AI inspection systems

- Torque-sensitive robotics with vision logic

🍱 Food, Packaging & Consumer Goods

- Automation of filling, boxing, sealing

- Food-grade wet blasting solutions

- QR/barcode traceability & AGV logistics

- IoT-based real-time monitoring

Our Journey with Japanese Excellence

2023 – SAMENSO Founded

Established by a Japanese automation expert with 12+ years experience, focused on delivering precision machines for Japanese industries.

2023 Q2 – Team Expansion

Formed a core engineering & management team with Japanese-style training and methodology.

2024 – Global Client Onboarding

Began serving Japanese manufacturers worldwide with full in-house solutions – design to install.

2024 – Japanese Engineering Support

Built a bilingual team with native Japanese engineers and sales staff to enhance global project communication.

Certifications & Strategic Alliances

MSME Registered

Recognized under India’s MSME scheme as a startup company committed to advanced manufacturing for Japanese clients.

ISO 9001 (Planned)

Certification process underway to align with international quality standards and Japanese tier-1 audit requirements.

Nagoya Partner

Sales and service partner based in Nagoya, Japan providing pre-sales support and after-sales service in local language.

Japanese Engineering Collaboration

Collaboration with Japanese experts ensures our engineering quality, technical documents, and workflows match Japan’s expectations.

“Built in India. Engineered for Japan.”

Experience Japanese-Grade Automation — Built for You

From concept to commissioning, we build factory automation systems that align with Japan’s precision standards.

Now offering wet blasting machine demo:

– At your facility (with transport charges)

– Or visit our office for a free hands-on trial

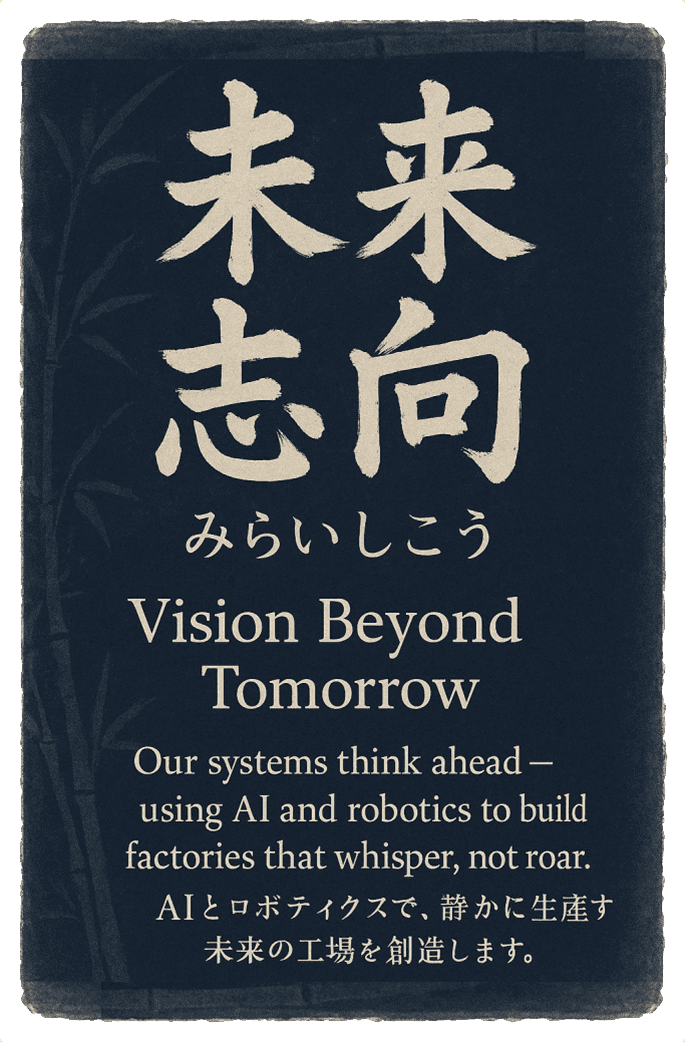

Three Pillars of SamEnSo – 和魂技術 (Spirit, Craft, Vision)

Our Flagship Solutions:

Framed as “Intelligent Tools of the New Kaizen”

(Kaizen = continuous improvement – a strong word in Japanese industry)

Our Philosophy – Beyond Industry 4.0:

Where Technology Listens Before It Acts.

Gemba 5.0 is not just smart. It’s sensitive. It’s not just fast. It’s thoughtful.

We don’t build machines that bark commands — we build systems

that observe, learn, and respect the rhythm of your factory floor.

Our innovation is shaped by the

real lives of people, parts, and processes

— not just algorithms.

Gemba 5.0 – The Five Dimensions

We Engineer Around:

- Vision – Seeing beyond pixels, understanding purpose

- AI – Learning the line, not just controlling it

- Zero Defect Systems – Quality woven into every motion

- IoT + PLC Harmony – Communication without confusion

- Human-Machine Resonance – Tech that supports, not replaces

If a system can’t feel your factory’s heartbeat,

can’t lead it. We don’t just automate tasks —

tune into your gemba, and engineer harmony.

INDUSTRIES WE SERVE

Driving Innovation in Key Industries

Automotive

We provide advanced wet blasting solutions for the automotive industry, ensuring smooth, high-quality finishes on parts. Our technology supports precision cleaning, surface preparation, and rust removal, boosting efficiency, reducing costs, and enhancing product longevity for both large-scale and specialized automotive applications.

Electronic

Our wet blasting solutions serve the electronics industry by providing precise surface preparation, cleaning, and finishing. Ideal for delicate components, our technology ensures high-quality results without damage, enhancing product reliability and performance while meeting stringent industry standards for electronics manufacturing.

Manufacturing

Our wet blasting solutions support the manufacturing industry by offering efficient surface finishing, cleaning, and preparation for various materials. With customizable options, our machines improve productivity, ensure high-quality finishes, and adapt to the specific needs of diverse manufacturing processes, boosting operational efficiency.